Streamline eVTOL aircraft propeller design with a server-based framework for MDAO studies

Written by Alexander Duggan and Vivek Ahuja

15 February 2023 · 10 min read

In the design of any complex system, design optimization is essential because it helps improve product performance, meet various stakeholder requirements, and reduce cost and time to market. In the automated search of the design space, design optimization makes extensive use of computer-aided-engineering (CAE the use of computer software to simulate and analyze product performance) simulations. Engineered systems combine sub-systems and components; each part is modeled by different physics and the performance assessment covers a range of engineering disciplines including: fluid-dynamics, structural, thermal, electro-magnetic, and many others. This combination is termed multi-disciplinary design analysis and optimization (MDAO, a framework that integrates multiple engineering disciplines to optimize complex systems). The motivation for using an MDAO framework is to have a proven method in place that can meet the demands of a changing and increasingly complex environment.

Why Multi-disciplinary Design Analysis and Optimization (MDAO) for eVTOL aircraft development

Over the last decade the emerging prevalence of Distributed Electric Propulsion (DEP, an arrangement of multiple electric motors and propellers across the airframe) in aviation has added a new paradigm to the aircraft design problem because it fundamentally changes how lift, thrust, and control are distributed across the airframe. Electric Vertical Take-off and Landing (eVTOL) aircraft work within a uniquely constrained multi-disciplinary environment. The propellers for this genre of aircraft must operate in cruise as well as in vertical and transitional flight modes. Some designs augment flow using a collection of electric motor-driven high-lift propellers (HLP, propellers designed to generate additional lift during low-speed flight) for lift augmentation in low-speed flight conditions, while other designs can provide additional thrust for vertical or short takeoff and landing (V/STOL). Several concepts aim to realize favorable interactions between the airframe aerodynamics and strategically integrated propulsors, achieving hitherto unrealizable performance benefits. These propellers must be structurally sound so that they can withstand complex vehicle transitions. They must be quiet so that aircraft can safely operate in densely populated urban environments in order to accomplish Urban Air Mobility (UAM) tasks.

FlightStream® aerodynamic modeling solver meets computational efficiency for MDAO aircraft studies

Early design exercises require tools having both high computational efficiency and sufficient fidelity because engineers must explore multiple concepts quickly while maintaining reliable performance predictions. However, the same highly coupled aero-propulsive interactions are difficult to model with sufficient levels of accuracy in early design stages (conceptual and preliminary). Commercial and open-source low- and mid-fidelity tools implementing vortex lattice methods, surface vorticity methods, seeded particle methods, or lifting line theory have emerged to fill this capability gap.

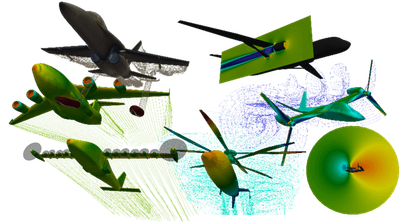

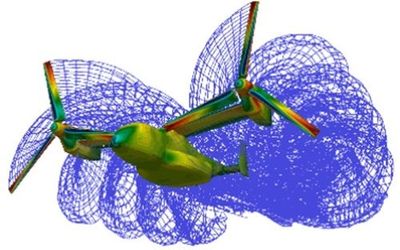

FlightStream® is a surface vorticity solver which provides reliable analysis of aerodynamic loads while maintaining computational efficiency levels required by most MDAO pipelines

By using reliable, efficient tools in the earlier phases of design, more mature designs emerge early in the design process. While Computational Fluid Dynamics (CFD, a simulation technique for analyzing fluid flow around surfaces) tools which solve the unabridged continuum Navier-Stokes Equations provide the necessary fidelity to refine designs they are often too computationally demanding to guide early design decisions effectively.

Flightstream allows for rapid analysis of unconventional aircraft using a unique surface vorticity, flow-separation and viscous analysis capability for both powered and unpowered configuration.

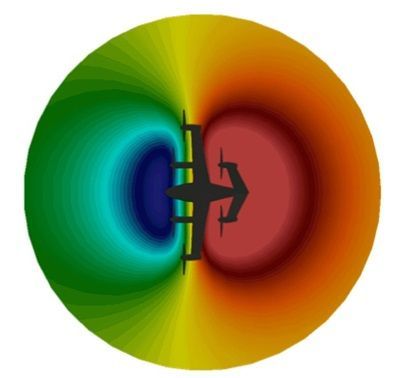

FlightStream® is a surface vorticity solver which provides reliable analysis of aerodynamic loads while maintaining computational efficiency levels required by most MDAO pipelines. The solver uses vorticity sheets to provide solutions in minutes. This solver has also been coupled with an aeroacoustics capability to allow the modeling of noise in early design stages.

ESTECO VOLTA SPDM platform facilitates MDAO studies for eVTOL propeller performance improvements

We partnered with Research in Flight to showcase a methodology for optimizing an eVTOL propeller geometry to meet stakeholders’ competing requirements and key performance metrics. Commonly such a complex task would be too time-consuming and costly to solve. Especially when high-fidelity volume-based Computational Fluid Dynamics (CFD) becomes the bottleneck.

We addressed this design challenge by combining ESTECO VOLTA SPDM (Simulation Process and Data Management) platform and its MDAO capabilities with the FlightStream® aerodynamic analysis tool. The physics are captured by incorporating multiple analysis and disciplines.

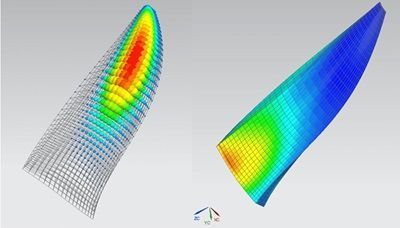

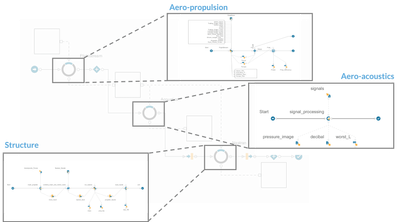

Aero-propulsion (FlightStream), Aero-acoustics (FlightStream) and Structure (NX Nastran) analysis

Modeling the eVTOL propeller geometry

In particular, the eVTOL propeller was geometrically modeled using Bernstein polynomials feeding cross-sectional data of the propeller to the FlightStream Component Cross-Section (CCS) file format. The CCS file [4-6], is a text file that allows the user to import aircraft geometry into FlightStream in a manner suitable for automatic mesh generation. The CCS file also allows the user to define control surfaces and set several meshing options. For this work, a FORTRAN script was written to automatically convert the Bernstein polynomial data into sectional cross-section data for the CCS file format. The process by which this geometry is conceived and the means by which it is built are crucial aspects to the development of the optimization formulation.

The process by which the geometry is constructed should be accurate and replicable so that results can be validated and reused across future design iterations. Furthermore, the design space should not be limited by the design tool used to create the geometry.

Building the automated MDAO workflow

Then these parameterized models for aero-propulsion, aero-acoustics, and stress analyses were automated into the ESTECO modeFRONTIER modular MDAO workflow and published on VOLTA SPDM platform ready to be executed.

VOLTA SPDM platform leverage ESTECO’s modeFRONTIER simulation process automation workflow

This workflow enabled an optimization framework for eVTOL propellers with the goal of satisfying four discipline related objectives. In terms of aero-propulsion discipline, we were interested in maximizing the thrust while minimizing the torque of the propeller. From the acoustics discipline, the goal is to be as quiet as possible, so we were interested in minimizing the sound pressure level. Finally, we included a Finite Element Analysis (FEA, a method for evaluating structural performance under stress) discipline where we wanted to minimize the propeller mass and make sure that our stresses were within allowable limits and therefore meeting requirements.

We used the ESTECO proprietary pilOPT algorithm to find an optimal geometry for the eVTOL propeller with the best tradeoff between the objectives listed above. The proprietary pilOPT algorithm is one of our most advanced optimization strategies. It self-adapts to your design problem; adjusting strategies on the fly as required to get you a pareto frontier with tradeoff space coverage in a reasonable amount of time.

Once the MDAO workflow has been set up, it is published on the ESTECO VOLTA enterprise platform to be executed. Thanks to its web interface and the collaborative environment for SPDM, VOLTA speeds up the communications among the subject matter experts and the stakeholders. The framework also enforces standardization and the formalization of simulation and business processes as an institutionalized method, promotes knowledge reuse, and facilitates the sharing of needed resources.

Through VOLTA Data Manager, subject matter experts can store, version and share their CAD/CAE models and MDAO workflows securely in a web environment

Collaborative roles within VOLTA

In VOLTA, each subject matter expert (SME) owns and is responsible for maintaining their part of the overall MDAO study so that domain-specific knowledge remains accurate, traceable, and up to date:

- The CAD expert generates the geometry of the blades providing a parametric model and the CAD solution used to vary the propeller’s shape.

- The aerodynamic expert sets up the aerodynamic simulation model, which uses the geometry model to evaluate its aerodynamic performance using FlightStream®, and makes it available to the structure expert to impose aerodynamic loads on the blade.

- The acoustics expert also uses the output of the aerodynamic simulation to calculate sound pressure levels at various observer positions.

- The simulation expert concates all those models into the automated MDAO workflow to be easily executed from a web interface and re-used for further analysis.

With VOLTA Planner, subject matter expert can execute MDAO workflows from an intuitive web interface

Once the workflow was set up, the simulation expert created and executed an optimization plan through the VOLTA web interface:

- Add a Plan: Define the MDAO study to optimize propeller shape while satisfying all design requirements.

- Select the study type: Choose between a Design of Experiments (DOE) or an optimization routine to explore the design space.

- Configure parameters: Adjust performance metrics, input variables, and design constraints through the VOLTA Planner interface.

- Create multiple plans: Build several design studies on top of the same workflow to test alternative exploration strategies and compare outcomes.

Executing and scaling MDAO studies

From the execution perspective, different simulation components run on varied resources:

Local execution: CAD solvers and internal codes typically run on local machines.

Scalable execution: Aerodynamic simulations may require extra computing power or licenses, often executed through cloud services.

Secure orchestration: ESTECO’s job scheduling technology manages distributed execution across public, private, or hybrid clouds — such as Amazon EC2 — while ensuring data protection via VPNs and secure communication protocols.

Finally, stakeholders interested in the results of the optimizations can easily access and select the best propeller shape designs via the VOLTA Advisor web dashboard.

VOLTA Advisor enables subject matter experts to create web-based post-processing dashboards for analyzing MDAO studies

The VOLTA Advisor acts like the Authoritative Source Of Truth (ASOT, a single reliable data reference for all stakeholders) for trade space studies on the web. In this way, design stakeholders can log in, view the same data as all other stakeholders, apply their preferences, requirements, and performance goals. In this case, the performance goals would be sound/noise levels, thrust and torque of the propeller design, along with ensuring stress requirements are met. After these filters are applied to the data, they could make tradeoff decisions quicker and in a collaborative way rather than copy data and static images into powerpoints which are shared via email with no traceability at all.

Conclusion

This case highlights how ESTECO empowers organizations to bring innovative aircraft concepts to life faster and more efficiently. By integrating the VOLTA SPDM platform with Research in Flight’s FlightStream® solver, teams can automate and manage complex MDAO workflows to optimize eVTOL propeller performance. By combining high-fidelity analysis, collaborative process management, and automated optimization, ESTECO enables engineers to achieve better trade-offs between aerodynamic efficiency, noise reduction, and structural strength, because all data and decisions remain fully traceable throughout the design cycle.

Key takeaways:

- MDAO connects multiple engineering disciplines for holistic design optimization.

- VOLTA automates simulation workflows and enhances team collaboration.

- FlightStream® enables fast, accurate aerodynamic modeling in early design stages.

- Integration of VOLTA and FlightStream® supports multi-objective propeller optimization.

- Outcome: reduced design time, improved performance, and data traceability.

Watch this webinar on MDAO studies to learn more how ESTECO's efficient server-based approach to MDAO combined with Research in Flight's aerodynamic analysis tools enable organizations to optimize eVTOL aircraft propeller design in a fraction of time.

Dr. Vivek Ahuja is the CEO and co-founder of Research in Flight, the developer of FlightStream. He holds a PhD in Aerospace Engineering from Auburn University. Dr. Ahuja’s work over the past decade has focused on theoretical and numerical subsonic aerodynamics, with an emphasis towards surface vorticity and its applications to attached and separated flows. Dr. Ahuja has developed many innovations with surface vorticity for high-lift flow and has been in charge of commercializing the FlightStream flow solver for the aerospace industry worldwide. He has authored many technical papers on these topics at conferences and in journals. Dr. Ahuja has held software development positions in the CFD industry and served as the principal investigator on several NASA, DoD and USAF SBIR programs.

Dr. Vivek Ahuja is the CEO and co-founder of Research in Flight, the developer of FlightStream. He holds a PhD in Aerospace Engineering from Auburn University. Dr. Ahuja’s work over the past decade has focused on theoretical and numerical subsonic aerodynamics, with an emphasis towards surface vorticity and its applications to attached and separated flows. Dr. Ahuja has developed many innovations with surface vorticity for high-lift flow and has been in charge of commercializing the FlightStream flow solver for the aerospace industry worldwide. He has authored many technical papers on these topics at conferences and in journals. Dr. Ahuja has held software development positions in the CFD industry and served as the principal investigator on several NASA, DoD and USAF SBIR programs.

ESTECO's efficient server-based approach to MDAO combined with Research In Flight's aerodynamic analysis tools enable organizations to optimize eVTOL aircraft propeller design.

Solve complex MDAO aircraft studies in a fraction of the time

ESTECO's efficient server-based approach to MDAO combined with Research In Flight's aerodynamic analysis tools enable organizations to optimize eVTOL aircraft propeller design.

Solve complex MDAO aircraft studies in a fraction of the time

ESTECO's efficient server-based approach to MDAO combined with Research In Flight's aerodynamic analysis tools enable organizations to optimize eVTOL aircraft propeller design.