BPMN in transportation: ESTECO's pivotal role in port logistics optimization

Written by Carlo Poloni

11 May 2021 · 8 min read

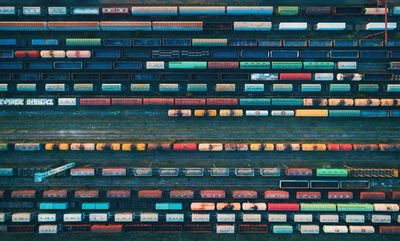

How Business Process Model and Notation helped one of the busiest ports in Europe modeling freight trains handling

Our BPMN editor, Cardanit, was part of a project used to optimize the railway system model of the port of Trieste, in Italy, to find out current bottlenecks. Documental procedures and train movements became business processes to analyze and scrutinize in order to further develop the project. This work is going to drive our Cardanit roadmap towards new ventures like optimization and simulation, which will become main features in the years to come. At the same time, the use of simulation process automation and numerical optimization technology enabled the creation of a digital twin of the port to optimize its planning and future developments.

Trieste is an Italian city, bordering with Slovenia, at the very top of the Adriatic Sea. Its port, strategically placed in the heart of Europe, has been historically an important hub for continental freight trade since the beginning of the 19th century. A free port, enjoying special privileges in organizational and legal terms, has made Trieste the terminus of regular direct ocean transportation services provided by the world’s main shipping lines not only to Eastern Europe, but also to the Far East and China.

Moving 57 million of tonnes of goods in 2018 and 9971 trains in 2019, the port needed to improve its capacity and optimize its operations.

Five steps to analyze and optimize the port rail system

With its position between two main transport corridors within Europe, Trieste Port is part of the EU project REIF (REgional Infrastructure for railway Freight transport) to promote regional rail freight as feeder infrastructure of the corridors. Specifically, the project focuses on:

- identifying measures to remove bottlenecks hindering further railway transport

- defining a railway operational system model to optimize the use of existing port railway infrastructures.

To develop the specific part concerning its railway improvement system, Trieste Port Authority teamed up with LIFT, a spin-off of the University of Trieste, and ESTECO. Because of this expertise we’ve been called to contribute to the main goals of the project:

- create a digital twin of Trieste Port Rail System

- estimate rail capacity

- optimize the functional planning and design of the port developments.

In a few words, the project goal was to analyze the structure of the internal rail processes of the Port of Trieste. The infrastructure complexity, the custom checks upon arrival and departure, the locomotive exchanges were just some of the constraints that needed to be worked on in order to increase the number of trains arriving and leaving the port.

It was pretty clear from the beginning of our involvement that our BPMN editor Cardanit had to play a major role in the development of the project turning the different actions to implement the port development into business processes to be modeled. In the plan, the advancement of the project was then subject to further analysis and simulation with the use of other software.

To proceed with the project, the different stakeholders agreed on the following five-step method:

- Modeling of the port railway system processes using the Business Process Model and Notation standard and our BPMN editor Cardanit

- Parameterization of the designed model with the Business Process Simulation (BPSim standard)

- Simulation with a third-party tool

- Optimization of the parameterizations with modeFRONTIER

- Approximation by means of Response Surface Model (RSM) to quickly explore all the parameter configurations of interest.

Modeling Trieste Port processes with BPMN

As the project foundations were laid out, the first stage was to analyze and model all the processes within the railway network of Trieste Port with the BPMN standard. The stakeholders chose this standard because its simplicity and expressiveness allow all the different parts involved in the project to speak and understand the same language.

Upon the start of the analysis, the stakeholders chose to describe all the documental procedures provided by Trieste Port Authority in one unique model with different processes, including:

- railway maneuvers necessary for the trains arrival and departure (from the main railway line to the terminals and vice versa)

- all the movements required to shunting locomotives to support these maneuvers.

Subsequently, a comparison and validation work with the DIF (Direzione Infrastrutture Ferroviarie - Railway Infrastructure Department) guaranteed the logical correctness of the model. After drafting the first high-resolution model, the analysts created a second one at a lower level of detail, with activities that require the same resources aggregated into single tasks.

This second model represented the most effective solution for the purposes of parameterization and subsequent simulation, therefore the following phases of the project focused on this second version of the BPMN model.

In Cardanit the final model was divided into four different tabs for each of the following processes:

- arrival, with the documental and maneuvering procedures required to the train arriving from the main railway line to move from the freight main station to the terminal where the train has to be unloaded. In this process, the analysts evaluated the different routes necessary to reach the different terminals, the possibility of performing single or shunting operations, and even possible variations caused by irregular checks at the gate. The arrival of the train to the freight main station triggers the departure process

- departure, which includes three possible start events, depending on the location of the departing train in one of the three terminals. This process also integrates the documental procedures with the maneuvering procedures. It also incorporates the possibility of any irregularity upon documental pre-checks, or at gate checks level. Furthermore, it analyzes the occurrence of carrying out single or double shunting operations. This process ends when the loaded train leaves the freight main station.

- locomotive release, activated by various intermediate events within the two processes of train departure and arrival, which describes the relocation of locomotives once released from the trains. Once their task is over, they are either moved to a depot or where a train waits for them

- locomotive recall, starting when a train needs a locomotive and running the relocation of the locomotives to where they are needed.

BPMN and Cardanit editor, the right tool to model complex business processes

Teresa Montrone, working in the Numerical Methods Group at ESTECO, was involved in the project from its beginning. In her words, “Using the sharing functionality in Cardanit was key in running the project, since all the stakeholders could access the BPMN projects and see its development as it happened. BPMN standard features like importing .xml files and creating sub-processes of the model definitely helped streamlining and speeding up all the processes. At the same time, using different tabs for each of the four processes was of aid in keeping all the information in one central repository and working on a less complicated model.”

How BPMN models evolved in simulation and optimization

Parameterization

After analyzing all the BPMN models, the analysts introduced the parameterization of these models with BPSim. The Business Process Simulation (BPSim) is a standard allowing to add further information to business process models captured in BPMN. The standard defines the parameterization and interchange of process analysis data allowing structural and capacity analysis of process models, providing for Pre and Post-execution optimization.

In the Trieste Port project parameterization included:

- the time required to process port activities

- the probabilities of the events and the priorities of the trains

- the employment of the resources (tracks and locomotives) by different tasks.

Simulation

In this stage analysts used a third-party software enabling discrete-event simulation. Comparing simulated and collected data enabled to calibrate and validate the model, allowing the identification of process bottlenecks.

Optimization

For the Optimization part a specific modeFRONTIER project has been created and the defined discrete event simulation engine became its black-box. This workflow was composed of two nested workflows: an external workflow calls an internal one in which the optimization is actually performed by using the modeFRONTIER algorithm MOGA-II. The goal of the internal optimization was the maximization of the number of trains completing the arrival or departure processes, while the external one controls the track and locomotive resources.

Approximation

Using an RSM (Response Surface Model) is an additional benefit that allowed to approximate the optimal values. In fact, such a type of approximation doesn’t reach the best results, but gives very good ones in a short time, by reducing the ‘noise’ around the data.

Simulation of different scenarios to support business processes and decision making

After getting these results, in order to check the solutions were correct, analysts compared them by using a third-party railway simulation tool, which validated their accuracy.

In the end, the integration of BPMN modeling with Cardanit, the use of BPSim and the optimization work done with modeFRONTIER allowed to face and optimize the railway complexity of the Port of Trieste.

The first results of these analyses are very promising and the collaboration with Trieste Port should continue to improve them in the future.

According to these results, simulation of different scenarios can be of great support for decision-makers to correctly design the future developments of any port railway infrastructure and for ESTECO there are other collaboration opportunities in the pipeline with other port authorities worldwide.

Giovanni Longo, Scientific Director at one of the main partners of the project, LIFT, said “Cardanit was key in the start of our venture with the Port of Trieste. One of its best features is the ‘automated report’. After modeling all those complex processes it was a relief to click a button to get a document with all the work so well explained to present to the Trieste Port Authority.”

“The adoption of modeFRONTIER”, continues Professor Longo, “has enabled to define the details of the engineering design process of optimizing port railway capacity through an intuitive interface, named ‘workflow’ within the software. It formulates all the logical steps composing the process, including the definition of its input and output variables.”